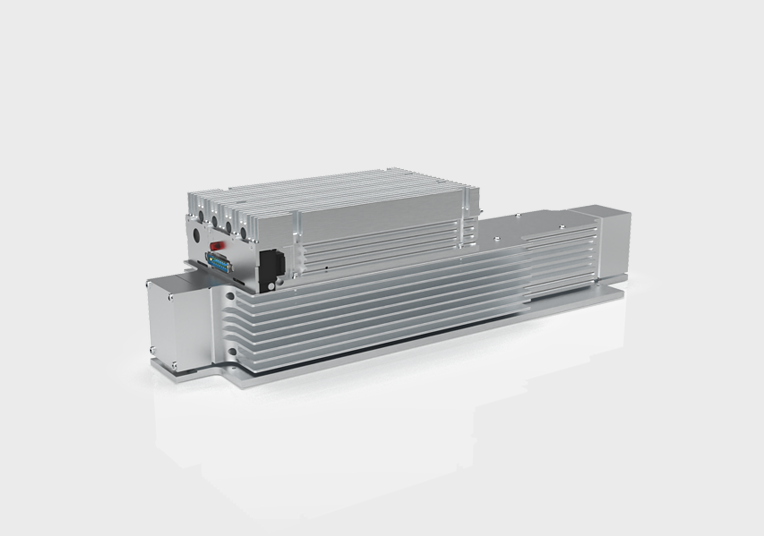

Raman Spectrometer

Spectroscopy Solutions

Measurement Systems 2

- Lock-in Amplifiers

- Impedance Analyzer

- Arbitrary Waveform Generators

- Phase Lock Loops

- Boxcer averagers

- Beam Profiler

- Autocorrelators

- MISS Mini imaging spectrometer

- Realtime FROG

Lock-in Amplifiers

Lock-in amplifiers are an essential part of research laboratories in areas such as optics and photonics, nanotechnology and materials science, quantum technologies, scanning probe microscopy and sensing. Thanks to a lock-in amplifier's ability to extract very small signals buried in noise, it is possible to uncover new science and expand the reach of experimental setups. The working principle of a lock-in amplifier, called demodulation or phase-sensitive detection, rests on mixing the measured signal with a reference frequency followed by low-pass filtering.

Choosing the modulation frequency of the measured signal makes it possible to move it away from dominant noise sources – which is especially relevant close to DC. The correct choice of filter settings can further improve the signal-to-noise ratio (SNR).

Our white paper and video on the principles of lock-in detection offer a more detailed discussion.

LabOne Instrument Control Software

All instruments are equipped with the LabOne® user interface providing time- and frequency-domain signal analysis tools in the form of a scope, a real-time data plotter, a DAQ module, a spectrum analyzer and a sweeper. Upgrade options include phase-locked loops, PID controllers, multi-demodulator and multi-frequency functionalities, as well as boxcar averagers and arbitrary waveform generators. These options expand the functionalities of the lock-in amplifiers; their installation does not require users to send the instrument back to us, as upgrade options are built on the FPGA-powered digital signal processing unit.

Impedance Analyzers

Zurich Instruments offers a powerful toolset for all types of impedance measurement. All instruments are equipped with the control software LabOne®, and additional options can be added to fulfill the requirements of the most demanding applications.

MFIA Impedance Analyzer

Key features

1 mHz to 5 MHz, 1 mΩ to 1 TΩ

Fast and accurate measurements

Ideal fit for DLTS, MEMS and ESR & ESL applications

Applications

Electrical engineering: sensors, supercapacitors, semiconductor characterization, DLTS, low ESR/ESL, ultra-high resistors, high-Q dielectrics.

Materials research: dielectrics, piezoelectrics, ceramics and composites, solar materials, geomaterials, thin films, nanostructure characterization

Bioimpedance: tissue impedance analysis, cell growth, food research, microfluidics, wearable sensors

Arbitrary Waveform Generators

Zurich Instruments offers arbitrary waveform generators (AWGs) that set new standards for channel density and integration with other measurement tools.

HDAWG: High-Density Multi-Channel AWGs

With the highest channel density and the most advanced synchronization features on the market, the HDAWG Arbitrary Waveform Generator is the choice for multi-channel applications with up to 64 channels. The noise characteristics of the 2.4 GSa/s, 16-bit signal generation and an ultra-low trigger latency unlock new levels of performance. Further, the LabOne® control software provides an intuitive and efficient way to program arbitrary signals.

UHFAWG: AWGs with Integrated Detection

The 2-channel UHFAWG Arbitrary Waveform Generator with 1.8 GSa/s and 14-bit D/A conversion is the only AWG with integrated detection that can be configured to the user's needs with a selection of measurement tools (Scope, Digitizer, Spectrum Analyzer, Lock-in Amplifier/Demodulation, Boxcar Averager, etc.) on its 600 MHz signal inputs. In this way, complex setups with non-sinusoidal excitation patterns can be radically simplified at the hardware and software level. It is also possible to eliminate clock synchronization issues associated with compound setups.

Phase-Locked Loops

Phase-locked loops (PLLs) are closed-loop negative-feedback control systems that maintain the phases of two periodic signals in a well-defined phase relation. Consequently, PLLs are versatile tools for measuring and tracking a signal's frequency, for extracting a given frequency component of the original signal while eliminating noise and spurious components, or for synthesizing new signals based on the input signal.

In addition, PLLs can provide feedback to an external system to drive it at certain points of its transfer function, for example at resonance, or to synchronize two external oscillators by tracking their beat note as often done in optical PLLs. This versatility makes PLLs great tools for physics and engineering applications such as scanning probe microscopy, MEMS, NEMS and resonators, electronic engineering, optics and photonics.

PLLs for Lock-in Amplifiers

All Zurich Instruments' PLLs are implemented by means of digital signal processing on an FPGA with multiple numerically controlled oscillators available as signal sources. The phase detector is realized as the dual-phase demodulator of a lock-in amplifier with a low-pass filter that rejects many of the unwanted spectral components.

Providing a clean signal to the PID controller increases the stability of the PLL. Zurich Instruments' PLLs can realize basic PLL configurations as well as more complex measurement and control schemes with a single instrument, because the PLLs are upgrade options for our lock-in amplifiers and can run in parallel with other built-in functionality such as feedback controllers, demodulators, and data capture and analysis tools. This white paper provides a more detailed discussion of lock-in amplifiers and phase detection.

LabOne instrument control software

All Zurich Instruments' lock-in amplifiers are equipped with the LabOne® toolset that allows users to fully characterize their system with a parametric sweeper, an oscilloscope, and many other data acquisition tools. For instance, it is possible to visualize the PID error as a histogram to spot deviations from a normal distribution, which may indicate that something in the setup does not work as expected. Further, the PLL's bandwidth can be measured under real experimental conditions using a frequency modulation method, as shown in the figure to the right.

Boxcar Averagers

Boxcar averagers are attractive tools to achieve a high signal-to-noise ratio (SNR) in a minimal amount of measurement time when working with low duty-cycle signals. Such signals contain relevant information only in a fraction of each period; outside that fraction only noise is present. Capturing low duty-cycle signals with high quality and the ability for real-time feedback is crucial in many applications in optics and photonics, nanotechnology and materials science, quantum technologies, scanning probe microscopy, and sensing.

The graphic below illustrates the principle of boxcar averaging: limiting the measurement to a well-defined temporal window in each period, indicated in grey, means that all signal components outside of that window are rejected. Unlike a regular digitizer or an oscilloscope, the measurement results are immediately available in the digital domain and as analog signals with a user-defined offset and scaling factors. Moreover, integrated PID controllers can process the results to create feedback loops and the lock-in amplifier units can perform additional demodulation on the boxcar results if an additional modulation is present.

Boxcar Averager for Lock-in Amplifiers

The Zurich Instruments Boxcar Averager operates as a high-speed digitizer synchronized to a reference oscillator that is phase-locked to the periodicity of the experiment. In the case of the laser repetition rate, for example, every data sample recorded at the input can be associated with the phase of the experiment and the signal components not synchronized with the experiment are strongly suppressed. The implementation based on an external reference signal removes the trigger jitter, and the digital realization enables a dead-time-free operation.

2 Boxcar Averagers for 600 MHz Lock-in Amplifier

2 periodic waveform analyzers

Baseline suppression

Zero acquisition dead time

User Benefits

Save time on high-quality measurements of low duty-cycle signals.

Choose the best-suited technique for every new experiment: boxcar averaging, lock-in detection or both.

Demanding schemes and methods such as double modulation, baseline suppression and feedback loop operation become straightforward to implement thanks to the LabOne toolset.

- Zurich Instruments AG, Switzerland

- All Beam Profiler

- BeamPro Compact

- BeamPro One-Inch Beam Profiler

- BeamPro Low-profile Beam Profiler

- BeamPro SWIR Beam Profiler

BeamPro Beam Profiler

Beam Profilers allow the measurement of the entire optical intensity profile of laser beams. They not only retrieve the beam diameter and position, but also the full spatial shape of the beam.

Available as

Compact version

Low profile

µ-Low profile

SWIR Range

One-inch

STAR software for all beam profilers

Live extraction of beam properties, even with resolutions larger than 20 Mpx

Several parameters and methods supported (ISO calculation included)

Enhanced background & hot pixels treatment for optimum dynamic and signal-to-noise ratio

Client / Server interface, allowing remote control through network

Advanced logging and permanent access to the 10 previous acquisitions

Live comparison with up to 10 different reference measurements

1-click installation, completely configurable, export assistant

- All Autocorrelators

- ROC Autocorrelator Single-Shot

- µ-ROC Worlds smallest autocorrelator

- MS-ROC Autocorrelator

ROC Autocorrelators

Pulse duration measurement made easy

Optical autocorrelators are used to measure pulse duration of ultra-short laser pulses. The principle is to create two copies of the laser beam of interest with a beam splitter. The copies are superimposed in a nonlinear medium (SHG crystal), where they interact generating a third beam. As the overlap of the two copies depends on the pulse duration, analysing the third beam allows to calculate the pulse duration.

Discover the autocorrelator models of Femto Easy

The autocorrelators of our ROC series offer a wide variety of benefits: The ROC Single-shot accompanies you on every experimental adventure with plenty of comfort. The µ-ROC Single-Shot impresses with its ultralow compact size and high-quality workmanship and brings you directly into machines and lasers (OEM integration) thanks to innovative technology. The MS-ROC is suitable for broad pulse ranges and allows the measurement of pulses from 5 fs to 40 ps / 25 fs to 80 ps.

Software

The Femto Easy software has been designed to be user friendly and intuitive. This is a modern software compatible with touchscreen that can run either under Linux or Windows. It allows distant control of the devices via PC, tablet or smartphone. We can also provide custom software developments upon request.

MISS 2D spectrometer

Acquire spatially-resolved spectrum of laser beams

MISS (Mini Imaging Spatial Spectrometer) gives access to the spatially-resolved (2D) spectrum of laser beams. Thanks to its unique compactness, MISS allows vertical and horizontal spatial chirp measurements at any position of your beam path. It can easily be integrated at different stages of amplified laser systems. It can be used in free-space mode to take benefit of the spatial resolution, or conveniently with a fiber input, like a regular spectrometer (plug & play SMA fiber connector included).

2D spectrum characterization for many common types of lasers

A conventional spectrometer allows you to know the spectrum for your laser, i.e. the intensity of each wavelength (or frequency) present in your laser. Most of regular spectrometers give an average spectrum (1D), where imaging spectrometer allows you to know the spectrum at different positions along the laser beam cross-section (2D).

Our MISS spectrometer gives you a two dimensions image, one dimension being the position in one diameter of the beam, the other being the spectrum at this position.

Software

Like every Femto Easy product, the MISS comes with a powerful and very user friendly software, especially designed for touch screens, in order to give you the best user experience.

Realtime FROG

High-resolution FROG with visual feedback on all important pulse characteristics: pulse duration, spectral width, chirp, pulse front tilt, phase modulation, dispersion.

Frequency-Resolved Optical Gating allows for a complete recovery of pulse intensity and phase of ultrashort pulses with complex shapes. It can retrieve the full time-dependant electric field and the equivalent optical spectrum with spectral phase. In other words, FROG allows you to know the duration of your laser pulses, but also how to deal with the spectral phase to achieve the shortest possible pulse duration.

Discover the FROG models of Femto Easy

Femto Easy’s single-shot and multi-shot models come with unique features and different configuration options. Compare the two model ranges and discover which FROG system meets your ultra-short pulse measurement needs best.

Software

Fast FROG software comes with an optimized retrieval algorithm, that allows you to retrieve time and spectral information in real time.

Live extraction of shot-to-shot pulse properties: temporal profile intensity and phase, fundamental spectrum and phase, Chirp, Third-order dispersion.

Super-fast reconstruction speed and quality due to the combination of several algorithms (including the Ptychographic Iterative Engine)

High dynamic and low signal-to-noise ratio secured by enhanced background & hot pixels treatment

Remote control through network (Client / Server interface)

All data exportable into most common formats

Solar-2

- Sciencetech Inc.

- Ultratech a division of Veeco

- NANO-MASTER, Inc.

- Copper Welding of Solar Thermal Heaters

- Laser Scribbing of Thin Films

Sciencetech Inc., Canada

- SOLAR SIMULATION/ SOLAR SIMULATORS

- Solar PV testing Equipment

- Modular IV test equipment

- Monochromators and Accessories

- Tunable Light sources

- Light Sources

- Far Infrared Systems (THz)

- Customized Engineering Solution

Sciencetech Steady State Solar Simulators

Sciencetech solar simulators are highly configurable and with an impressive range of solar simulator options, our systems have been serving multiple researches and testing applications. Our solar simulator systems comply with standards such as ASTM, IEC and JIS and provides variability is design to accommodate researcher’s requirements. With over 30 years of experience in the solar simulator designing and manufacturing field, our systems provide

- Spectral emission closest to the sun’s spectrum

- High spatial uniformity

- High temporal stability

- Configurable orientations in illumination direction

- Variety of output collimation angles

- Variable illumination areas

- Easy to use, turn-key systems with full software control

- Multiple add ons and accessories such as fiber optic cables, beam turning units, filters and more

Ultratech a division of Veeco

Atomic Layer Deposition Systems (ALD)

Atomic Layer Deposition Systems (ALD)

Atomic Layer Deposition Systems

Device node shrinking continues, with 10nm and 7nm node in production, and development taking place down to 3nm. Our atomic layer deposition tools give you ultimate precision and uniformity for coatings at even the finest nodes.

Fiji – Plasma Enhanced ALD for R&D

Advanced Capabilities for Advanced Research

Our Fiji® series is a modular, high-vacuum thermal ALD system that accommodates a wide range of deposition modes using a flexible architecture and multiple configurations of precursors and plasma gases. The Fiji G2 is a next-generation ALD system capable of performing thermal and plasma-enhanced deposition.

We have applied advanced computational fluid dynamics analyses to optimize the Fiji® reactor, heater, and trap geometry. The system’s intuitive interface makes it easy to monitor and change recipes and processes as needed.

Phoenix – Batch Production ALD

Production Capabilities

The Phoenix® system is engineered for high throughput and maximum uptime in any fabrication environment, from pilot production to industrial-grade manufacturing. Technologists and researchers rely on the Phoenix® for repeatable, highly accurate film deposition on flat and 3D substrates alike. And with support for up to six individual precursor lines, the Phoenix® delivers solid, liquid, or gaseous process chemistries depending on your thin film needs. A compact footprint and innovative design makes the Phoenix® the practical choice for those with batch production ALD requirements.

Savannah – Thermal ALD for R&D

Advanced Capabilities for Advanced Research

Veeco is the leading provider of atomic layer deposition (ALD) systems for research and industry worldwide, delivering comprehensive services and versatile, turnkey systems that are accessible, affordable and accurate to the atomic scale. Thin film deposition is our expertise. Our Savannah® Series of thin film deposition tools exemplifies these competencies.

Savannah® has become the preferred system for university researchers worldwide engaged in ALD and looking for an affordable yet robust platform. We have delivered hundreds of these systems in the past decade. Savannah®’s efficient use of precursors and power-saving features substantially reduces the cost of operating a thin film deposition system.

NANO-MASTER, Inc.

NANO-MASTER, Inc.

Thin Film Deposition

-

E-Beam Evaporation

-

PECVD

-

Sputtering

-

Thermal Evaporation

Etching

-

Reactive Ion Etching

-

Deep Reactive Ion Etching

-

Ion Beam Milling

Thin Film Growth

-

PA-MOCVD - Table Top Plasma Assisted Metal Organic Chemical Vapor Deposition (PA-MOCVD)

Wafer Cleaning Systems

Wet Cleaning

-

Single Wafer Cleaners (SWC)

-

Large Substrate Cleaner (LSC)

-

Pelliclized and Unpelliclized Reticle

Dry Cleaning

-

Plasma Ashing Systems

Dual Chamber Systems

Space Simulation Systems

Nanotechnology 2

- Ultratech a division of Veeco

- MICROTECH srl

- Ecopia Corporation

- Semco Technologies

- SIOS Meßtechnik GmbH

- Winner Particle Instrument Stock Co. Ltd.

- Sciencetech Inc.

- NANO-MASTER, Inc.

- Copper Welding of Solar Thermal Heaters

- Laser Scribbing of Thin Films

- SVT Associates, Inc., USA

Ultratech a division of Veeco, USA

Atomic Layer Deposition Systems (ALD)

Atomic Layer Deposition Systems

Device node shrinking continues, with 10nm and 7nm node in production, and development taking place down to 3nm. Our atomic layer deposition tools give you ultimate precision and uniformity for coatings at even the finest nodes.

Fiji – Plasma Enhanced ALD for R&D

Advanced Capabilities for Advanced Research

Our Fiji® series is a modular, high-vacuum thermal ALD system that accommodates a wide range of deposition modes using a flexible architecture and multiple configurations of precursors and plasma gases. The Fiji G2 is a next-generation ALD system capable of performing thermal and plasma-enhanced deposition.

We have applied advanced computational fluid dynamics analyses to optimize the Fiji® reactor, heater, and trap geometry. The system’s intuitive interface makes it easy to monitor and change recipes and processes as needed.

Phoenix – Batch Production ALD

Production Capabilities

The Phoenix® system is engineered for high throughput and maximum uptime in any fabrication environment, from pilot production to industrial-grade manufacturing. Technologists and researchers rely on the Phoenix® for repeatable, highly accurate film deposition on flat and 3D substrates alike. And with support for up to six individual precursor lines, the Phoenix® delivers solid, liquid, or gaseous process chemistries depending on your thin film needs. A compact footprint and innovative design makes the Phoenix® the practical choice for those with batch production ALD requirements.

Savannah – Thermal ALD for R&D

Advanced Capabilities for Advanced Research

Veeco is the leading provider of atomic layer deposition (ALD) systems for research and industry worldwide, delivering comprehensive services and versatile, turnkey systems that are accessible, affordable and accurate to the atomic scale. Thin film deposition is our expertise. Our Savannah® Series of thin film deposition tools exemplifies these competencies.

Savannah® has become the preferred system for university researchers worldwide engaged in ALD and looking for an affordable yet robust platform. We have delivered hundreds of these systems in the past decade. Savannah®’s efficient use of precursors and power-saving features substantially reduces the cost of operating a thin film deposition system.

MICROTECH srl

MICROTECH srl

The LaserWriter pattern generator

The LaserWriter system by MICROTECH is designed for the definition of planar geometries and for surface diagnostics, in applications where maximum resolutions down to 0.7 µm are required. The system transforms a laser beam into a controlled writing tool for photolithographic mask fabrication or for direct in situ processing on planar substrates. Besides microlithographic applications, its optical apparatus and substrate motion management are also well suited for surface inspection or diagnostics. Hence, the same machine can be used first for producing a pattern and later for inspecting the results. The patterns are generated by accurately moving the target (mask or substrate) underneath a focused and scanning laser beam with proper wavelength. The performance and cost of the system are optimised for research and development or small/medium productions.

3-D LASER LITHOGRAPHY

MICROTECH has developed a complete microlithographic process for cylindrical surfaces. Such a process is suited for the fabrication of thin film coils, line arrays or generic patterns on the side surface of a cylinder, through the following steps:

- 1. Surface cleaning and polishing to optical quality

- 2. Coating with metal or dielectric thin film

- 3. Coating with resist

- 4. Laser writing of the pattern

- 5. Resist processing

- 6. Wet etching

- 7. Plating

Patterning resolution down to 5 micrometers can be achieved, including the plating process. Steps 3, 4 and 7 are very dependent on the special shape of the substrate and can be accomplished through specific equipement available from MICROTECH:

Resist deposition system. This special equipement allow the deposition of a thin and uniform resist layer on cylindrical surfaces. A resist thickness in the 1 to 5 micron range can be programmed. The substrate diameter can range between 1 and 100 mm.

Ecopia Corporation

Ecopia Corporation

◆ Super high temperature hall effect measurement system.

1) Features

- Super high temperature hall effect measurement system that is useful to flow gas into chamber with sample.

- Newly developed furnace that makes it possible to increase over 800℃ and use for measuring hall effect.

- Gas flow control system in order to flow various gas.

- Sample holder for high temperature. (keep the good contact on 800℃)

- High Temperature control system (DC power)

※ On condition of specific temperature with gas flow , new semiconductor materials have been developed to see electrical property’s change.

2) Application

i) Fuel cell (Polymer, electrolyte ceramics)

ii) Gas sensor (flammable organic solvent)

iii) Optical electrode and optical sensor (production and storage of hydrogen)

iv) Semiconductor for thermoelectric element.

Semco Technologies

Workhorse solution for a wide range of RTP/RTA applications with premium features and capabilities

Jipelec JETFIRST systems are compact and robust halogen lamp heated rapid thermal processing systems specifically designed to meet the requirements of research and small-scale production units with substrate size ranging from pieces of sample to 300-mm diameter. The JETFIRST benchtop design allows a quick and easy installation in the lab facilities. Its user-friendly operating interface is clearly structured and ensures for starting and using of the system in a few hours.

Features-

Single-wafer RTP furnace for process engineering and qualification

Cold-wall metal chamber design

High-performance crossed lamp technology

Atmospheric or vacuum thermal treatment

Gas introduction capability (any precursor).

Applications-

Rapid Thermal Annealing (RTA) and Contact alloying

Rapid Thermal Oxidation (RTO), deoxidation, and nitridation (RTN)

Rapid Thermal Diffusion (RTD) - e.g. Spin-on Dopant

Sulfurization, selenization and crystallization

Structural and mechanical stress relaxation

Printed metal contact firing.

SIOS Meßtechnik GmbH

-

Length Measurement Systems

-

Length and Angle Measurement Systems

-

Calibration Interferometer

-

Nanopositioning and Nanomeasuring Machine

-

Laser Vibrometer

-

Gauging Probe

-

Measurement and Calibration systems

-

Stabilized He-Ne Lasers

-

Climate Measuring Station

Precision in Measurement

True to our motto Precision in Measurement, we develop and manufacture laser interferometric and other precision measuring devices for calibration and nano measurement technology for measuring length, angle, vibration, straightness, mass, force and other measured variables with the highest resolution and low measurement uncertainty.

Winner Particle Instrument Stock Co. Ltd.

-

Laser Particle Size Analyzer

-

Spray Particle Size Analyzer

-

Nano-Particle Size Analyzer

-

Image Particle Shape and Size Analyzer

-

Inline particle size monitor

Laser Diffraction Particle Size Analyzer Principle

Laser Diffraction, also known as Static Light Scattering, has become one of the most widely used particle sizing distribution techniques across various industries. Samples can be analyzed on either a liquid suspension or dry dispersion basis. The sample material is passed through a laser beam which results in the laser light scattered at a wide range of angles. Detectors placed at fixed angles measure the intensity of light scattered at that position. A mathematical model (Mie or Fraunhoffer Theory) is then applied to generate a particle size distribution. The final result is reported on an Equivalent Spherical Diameter Volume basis.

Particle Size by Laser Diffraction is widely recognized by numerous standards and guidance agencies such as the ISO13320-1:1999,GB/T19077.1-2008,Q/0100JWN001-2013 This technique’s ability to perform dry or liquid dispersion analyses make it a good choice for general particle sizing applications and its broad dynamic range (sub-micron to millimeters) has proven useful to the environmental, pharmaceutical, food, health, beauty,petrochemical, mineral, metal and many other industries.

Sciencetech Inc.

SOLAR SIMULATION/ SOLAR SIMULATORS

SOLAR SIMULATION/ SOLAR SIMULATORS

-

Steady state solar simulators

-

Flash Solar simulators

-

Solar PV testing Equipment

-

Modular IV test equipment

-

Monochromators and AccessoriesTunable Light sources

-

Light Sources

-

Far Infrared Systems (THz)

Sciencetech Light Sources

Sciencetech offers light sources from UV to Infrared. A complete light source typically includes the lamp mounted in a housing with condensing/coupling optics, a power supply and all the necessary cables and hardware. For spectroscopic application, a DC stabilized power supply is required. Arc sources also include a stand alone igniter to break down the gas and establish the plasma discharge. A full line of accessories such as light condensers and collimators, filters, optical feedback units output stabilization and light shutters are available.

NANO-MASTER, Inc.

Thin Film Deposition

Etching

Thin Film Growth

Wafer Cleaning Systems

Wet Cleaning

Dry Cleaning

Dual Chamber Systems

Space Simulation Systems

Copper Welding of Solar Thermal Heaters

For more information please contact us

Laser Scribbing of Thin Films

For more information please contact us

Industrial Laser 2

- UV Laser

- Picosecond Laser

- CO2 Laser

- Laser Cutting Machine

- Laser welding machine

- Additive Manufacturing

- Laser Micromachining

- Optical Fiber Processing

- AUTOMOTIVE

- MEDTECH

- CONSUMER

- Plastic Welding Machine EVO 2800

A picosecond laser is a type of laser that emits optical pulses with a duration that lies between 1 picosecond and approximately tens of picoseconds. This characteristic of picosecond lasers allows them to be categorized as ultrashort pulse or ultrafast lasers.

10 W to 150 W Lasers

The ULR series of CO2 lasers for OEM use are based on a sealed, RF pumped, slab design that produces a high-quality beam. These lasers can be operated in CW mode or modulated to control average power. Modulation is accomplished by varying the pulse width of the input signal.

In the 10 W to 150 W lasers, RF electrodes are spaced apart to allow the laser beam to form without influence of the electrodes, delivery excellent near- and far-field quality with minimal wave-guide effects.

The folded resonator design allows generation of power in a compact package.

Working principle: Cutting is achieved by powerful laser focused on object to cause instant melting and evaporation, with xenon lamp as the generator. Automatic cutting is controlled by digitalized mechanic system .This machine has condensed the technologies of laser, digital,and precise mechanics.

Advantages:

Smooth and fine edge or surface and small distortion.

Higher cutting speed and low cost, operation safe and stable function.

Imported servo motor and gearing system to guarantee precise cutting.

The dedicated software enables graphic or text to be instantly designed or processed.Flexible and easy operation.

Products applications: Sheet metal cutting Stainless steels cutting Spectacles frames cutting Accessories fabrications Hardware fabrications Automotives parts Advertisement arts Stainless steel decorations Kitchen appliances Stainless steel racks Stainless steel accessories Signboards Electrical appliances Signage, Furniture And more others which needed precision cutting of raw materials.

Applicable materials: Stainless steels Carbon steels Stainless iron Zinc coated iron sheets Aluminum alloys Aluminum Copper Rare metals And certain types of ceramics. Owing to the rich industry experience, we have been able to provide the customers with a commendable assortment of Laser Cutting and Engraving Machine. You simply won't find more feature-filled systems than those in the Laser Machine. Each feature has been designed with you in mind, and how you can get the most from the laser. You'll find features that improve connection capabilities, simplify project setup, and much more.

Laser welding is an advanced welding process technique, working with 4 axises control by the system, it able to welding various different shape items, the workpiece no distortion; no colour change; the weld point smooth, this laser welding machine widely applied to process jewellery; horologe; electric products; eyeglasses frame and some industries where require good welding effect.

The 4 axises linkage laser welding machine is able to do spot-welding, also can do the continuous welding; butt welding; stitch welding, seal welding, etc., the weld width small and heat-affected zone is small, no deformation.

Due to its characteristics of a high-beam quality, high penetration rate and transmission via fibres, Dynotech Instruments, with its global laser marking solutions is widely praised for precision spot welding. With adjustable supply output and a feedback control system for the laser power, helps stabilise the laser energy while also improving the consistency of the welding products. Our laser welding machine is most suitable for successful integration with automated production lines.

AconitySYSTEMS

LASER POWDER BED FUSION

Aconity3D offers several standard 3D printing machines, which cover a wide range of needs. On top, the machines can be modified easily by Aconity's modular platform and therefore enable tailor-made additive manufacturing solutions.

Aconity3D is specialized in the design and distribution of modular machine tools for powder bed based laser beam melting of metals. With the AconityPLATFORM, machines can be configured for your specific applications, thus extending the range of applications for this innovative manufacturing technology and allowing it to be used on an industrial scale. The open configurable Aconity3D systems combine maximum functionality with unique reliability. Our basic machine types, in combination with modular additional specifications, open up a wide range of application possibilities and can be tailored to specific customer requirements. Configure your system using our online machine configurator or contact our experienced staff for application-specific advice. We will support you at every stage, from identification and specification to the satisfaction of your specific needs. We look forward to hear from you.

Providing solutions for the most challenging industrial problems with decades of expertise in Laser welding technology

Laser micromachining offers the never witnessed before, a wide range of advantages for processing of materials in an ever-rising range of applications. Our laser micromachining and processing solutions support high-versatility solutions ranging from sub-micron tolerance to laser scribes that are kilometres long.

We provide an expansive range of laser technology that allows for the laser process to be in tune with the choice of material and the features, accompanied by high control over the interaction between the materials. We also master the control of laser energy delivery to an extent that our solutions can be effectively applied for thermal or heat-treatment procedures in addition to welding and vaporization for the purpose of high accuracy in micro-hole drilling procedures. The properties of our laser equipment allow for selective separation of one material from another, wherein the beam can be scanned to cater for features like laser marking, scribing, drilling, cutting, 3-D milling and dicing.

Making new applications possible with unique laser technologies that do what traditional fabrication techniques can’t.

Explore new engineering possibilities. OpTek has an extensive and innovative laser processing toolbox that enables applications that would be difficult or impossible to achieve with conventional optical fiber processing techniques.

Traditional abrasive and tool-based cleaving, lensing, and stripping methods are limited in the geometries they can achieve; are prone to abrasion, chipping, and other imperfections that can only be discovered in a separate inspection step; and can cause significant yield loss. OpTek’s laser-based methods solve all these issues—enabling simultaneous processing and inspection of precise design features for almost any specification, with virtually 100% first-pass yield.

Examples of our laser processing toolbox for fiber processing applications include:

1. Laser cleaving, including cylindrical, tapered, conical, angled and flat. These forms are used to provide high coupling efficiency between optical fibers and the laser source or receiver. Applications include telecommunications, data communications, fiber lasers, biomedical devices, energy exploration and production, gyroscopes, and a range of sensing applications.

2. Laser lensing, including conical, wedge, and biconic. High-performance lens forms are created directly on the end of optical fibers, with the unique ability to cleave and lens fibers already assembled into fixtures or ferrules. Applications include radial light emission for medical and dental procedures; probes for biomedical spectroscopy; light focusing for high-efficiency coupling with waveguides, source and detector coupling in telecom and military applications; and many others.

3. End capping. This reduces power densities to increase the damage threshold of the fiber component. It can also be used to modify beam shape emission through numerical aperture or mode field diameter manipulation or to modify beam direction and properties. Applications include high-energy beam delivery in defense, medicine, and a variety of sensing systems.

4. Laser stripping. Acrylate, polyimide, and other buffers can be removed through a non-contact process, with precise dimensional control for both end-stripping and window-stripping. Applications include medicine, defense, aerospace, undersea, and others that require ultra-high reliability. Advanced fiber assemblies: OpTek can also build complete, turnkey fiber optic assemblies for any application requirement, including terminators and connectors, feed-through tubes, solders, fiber Bragg gratings, and harsh-environment probes. With a single source for complete fiber assemblies, you can simplify your supply chain and count on reliable delivery and performance.

Whether you contract the work to OpTek or perform it yourself using OpTek technology, we help make your innovative new designs manufacturable. Let’s talk about your ideas and how to bring them to reality.

Shaping a safer, more efficient autonomous vehicles since decades

As a partner for provision of technological solutions, we empower our customers in the automotive industry with customer-centric and flexible laser systems. Our innovative solutions help bring futuristic automotive parts to life, be it the engine management or sensors the auto drive feature. At Dynotech Instruments, we thoroughly understand the importance of delivering the right service and equipment for effective functioning of all automotive industrial practices.

AUTOMOTIVE - MOBILE AND INNOVATIVE

As a technology partner, we inspire our customers in the automotive industry with highly flexible and customer-specific laser systems. We realize innovative joining solutions for future-oriented vehicle components from the interior, the drive train, to components for engine management, sensors for autonomous driving, electric drives or batteries. Our systems used worldwide are designed for smooth 24/7 production. We know how important the customers of our customers are and we can deliver the right service in the Evosys Group at the same time.

Reliable and safe medtech instruments that support constant development of new treatment methods

The consistency in the development of novel diagnostic and treatment processes has led to a rise in the significance of developing production processes in the healthcare sector that are reliable. We support you with our solutions backed by years of experience and expertise that help with the production processes in the medtech industry starting from the very initial developmental steps up to the final production outcomes. Facilitating the execution of top-priority Medtech requirements is our motto and our laser welding equipment help serve that meeting the GMP standards.

MEDTECH - SAFE AND RELIABLE

The constant development of new treatment methods is rapidly increasing the importance of reliable production processes in the healthcare sector. We support you with our engineers and their many years of experience in this field from the very first development steps for new products and associated joining tasks through to complete solutions for your production. Absolute reliability, complete documentation and the implementation of the highest cleanliness requirements are always in the foreground. Laser welding of plastics is the ideal process to meet these requirements. Production according to GMP standards is easy to ensure with EVOSYS equipment.

Facilitating particle-free and cost-effective operations through laser welding technology for plastics

Innovative designs and high-quality packaging are the requests that we most commonly encounter in the consumer industry. With our in-depth knowledge and expertise of a wide range of production processes, we provide the solutions and support that the consumer industry is exactly looking for. Dynotech Instruments’ equipment for laser welding of plastics is the best choice for the consumer industry.

CONSUMER - FAST AND EFFICIENT

Miniaturization, design and extreme packing density are the most common requests we encounter in the field of consumer products. With our process and production knowledge we provide support at an early stage. This means that targets can usually be exceeded. But laser welding of plastics can also be the best option for everyday products. EVOSYS systems are the best choice in any case.

The EvoWeld is a universal machine for plastic welding with laser, especially for the processing of small and medium series. Depending on the application, the system can be equipped with different laser sources and optical modules, thus offering a wide range of applications.

With a footprint of approx. 1 m², the system fits into any application environment. Virtually maintenance-free and service-friendly, the EvoWeld is predestined for use in 24/7 production. For comfortable operation, the system is equipped with the intuitive EvoLaP process software as standard and can therefore also implement a wide range of different processing tasks in the field of laser welding of Plastics.

Industrial Laser

- UV Laser

- Picosecond Laser

- CO2 Laser

- Laser Cutting Machine

- Laser welding machine

- Additive Manufacturing

- Laser Micromachining

- Optical Fiber Processing

- AUTOMOTIVE

- MEDTECH

- CONSUMER

- Plastic Welding Machine EVO 2800

Working principle: Cutting is achieved by powerful laser focused on object to cause instant melting and evaporation, with xenon lamp as the generator. Automatic cutting is controlled by digitalized mechanic system .This machine has condensed the technologies of laser, digital,and precise mechanics.

Advantages:

Smooth and fine edge or surface and small distortion.

Higher cutting speed and low cost, operation safe and stable function.

Imported servo motor and gearing system to guarantee precise cutting.

The dedicated software enables graphic or text to be instantly designed or processed.Flexible and easy operation.

Products applications: Sheet metal cutting Stainless steels cutting Spectacles frames cutting Accessories fabrications Hardware fabrications Automotives parts Advertisement arts Stainless steel decorations Kitchen appliances Stainless steel racks Stainless steel accessories Signboards Electrical appliances Signage, Furniture And more others which needed precision cutting of raw materials.

Applicable materials: Stainless steels Carbon steels Stainless iron Zinc coated iron sheets Aluminum alloys Aluminum Copper Rare metals And certain types of ceramics. Owing to the rich industry experience, we have been able to provide the customers with a commendable assortment of Laser Cutting and Engraving Machine. You simply won't find more feature-filled systems than those in the Laser Machine. Each feature has been designed with you in mind, and how you can get the most from the laser. You'll find features that improve connection capabilities, simplify project setup, and much more.

The laser welding is an advanced welding process technique, working with 4 axises control by system, it able to welding various different shape items, the work piece no distortion; no colour change; the weld point smooth, this laser welding machine widely applied to process jewelry; horologe; electric products; eyeglasses frame and some industries where require good welding effect.

The 4 axises linkage laser welding machine is able to do spot-welding, also can do the continuous welding; butt welding; stitch welding, seal welding, etc., the weld width small and heat-affected zone is small, no deformation.

Measurement Systems

- Lock-in Amplifiers

- Impedance Analyzer

- Arbitrary Waveform Generators

- Phase Lock Loops

- Boxcer averagers

- Beam Profiler

- Autocorrelators

- MISS Mini imaging spectrometer

- Realtime FROG

Industrial Laser

- UV Laser

- Picosecond Laser

- CO2 Laser

- Laser Cutting Machine

- Laser welding machine

- Additive Manufacturing

- Laser Micromachining

- Optical Fiber Processing

- AUTOMOTIVE

- MEDTECH

- CONSUMER

- Plastic Welding Machine EVO 2800

Working principle: Cutting is achieved by powerful laser focused on object to cause instant melting and evaporation, with xenon lamp as the generator. Automatic cutting is controlled by digitalized mechanic system .This machine has condensed the technologies of laser, digital,and precise mechanics.

Advantages:

Smooth and fine edge or surface and small distortion.

Higher cutting speed and low cost, operation safe and stable function.

Imported servo motor and gearing system to guarantee precise cutting.

The dedicated software enables graphic or text to be instantly designed or processed.Flexible and easy operation.

Products applications: Sheet metal cutting Stainless steels cutting Spectacles frames cutting Accessories fabrications Hardware fabrications Automotives parts Advertisement arts Stainless steel decorations Kitchen appliances Stainless steel racks Stainless steel accessories Signboards Electrical appliances Signage, Furniture And more others which needed precision cutting of raw materials.

Applicable materials: Stainless steels Carbon steels Stainless iron Zinc coated iron sheets Aluminum alloys Aluminum Copper Rare metals And certain types of ceramics. Owing to the rich industry experience, we have been able to provide the customers with a commendable assortment of Laser Cutting and Engraving Machine. You simply won't find more feature-filled systems than those in the Laser Machine. Each feature has been designed with you in mind, and how you can get the most from the laser. You'll find features that improve connection capabilities, simplify project setup, and much more.

The laser welding is an advanced welding process technique, working with 4 axises control by system, it able to welding various different shape items, the work piece no distortion; no colour change; the weld point smooth, this laser welding machine widely applied to process jewelry; horologe; electric products; eyeglasses frame and some industries where require good welding effect.

The 4 axises linkage laser welding machine is able to do spot-welding, also can do the continuous welding; butt welding; stitch welding, seal welding, etc., the weld width small and heat-affected zone is small, no deformation.

Laser and Photonics

Sources

- Lamp

- DPSS

- Gas Laser

- Single Frequency He-Ne

- CO2

- TEA CO2 Laser PaR Systems (Pty), South Africa

- Ultrafast Pulsed Lasers

- Femtosecond Laser

- Picosecond Laser

- Nanosecond Laser

Detection

HNü 128 - The EMCCD camera optimized for speed

HNü 240 – The EMCCD camera optimized for the highest AO performance

HNü TDI - The CCD camera optimized for industrial imaging

HNü 512 - The EMCCD camera optimized for performance

HNü 1024 - The EMCCD Camera optimized for wide field of view

EM N2 - The liquid nitrogen-cooled EMCCD & CCD camera

Vacuum compatible cooling

4K EMCCD solutions

System

Accessories

- Lambda Research Optics, Inc. Korea

Positioning System

Fiber Optics

Fast Axis Collimator Lenses (FACs) on bottom tabs

Slow Axis Collimator Lenses (SACs)

Precision Molded Glass Optics

Plano Optics

Micro Lenses for Imaging Systems

FISBA READYBeam™

Micro Laser Modules

Customized Optical Systems

Laser Beam Shaping Optics

Imaging Optics

Micro Imaging Systems