Industrial Laser 2

- UV Laser

- Picosecond Laser

- CO2 Laser

- Laser Cutting Machine

- Laser welding machine

- Additive Manufacturing

- Laser Micromachining

- Optical Fiber Processing

- AUTOMOTIVE

- MEDTECH

- CONSUMER

- Plastic Welding Machine EVO 2800

DX UV Air-Cooled Series

Standard UV Laser

DX Series Short Pulse Nanosecond Lasers

Short Pulse Nanosecond Laser

DC UV Series

Nd: YLF Laser

A picosecond laser is a type of laser that emits optical pulses with a duration that lies between 1 picosecond and approximately tens of picoseconds. This characteristic of picosecond lasers allows them to be categorized as ultrashort pulse or ultrafast lasers.

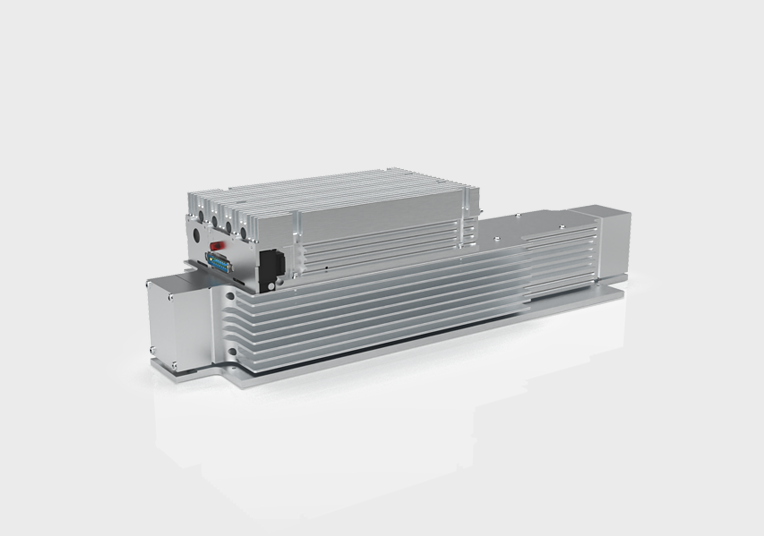

10 W to 150 W Lasers

The ULR series of CO2 lasers for OEM use are based on a sealed, RF pumped, slab design that produces a high-quality beam. These lasers can be operated in CW mode or modulated to control average power. Modulation is accomplished by varying the pulse width of the input signal.

In the 10 W to 150 W lasers, RF electrodes are spaced apart to allow the laser beam to form without influence of the electrodes, delivery excellent near- and far-field quality with minimal wave-guide effects.

The folded resonator design allows generation of power in a compact package.

Integrated Air

ULR lasers configured for integrated air cooling contain fans and heat sinks designed to allow the laser to operate efficiently with no external cooling.

Basic Air

ULR lasers configured for basic air cooling do not include fans. The integrator is responsible for ensuring adequate cooling, per ULS specifications.

Working principle: Cutting is achieved by powerful laser focused on object to cause instant melting and evaporation, with xenon lamp as the generator. Automatic cutting is controlled by digitalized mechanic system .This machine has condensed the technologies of laser, digital,and precise mechanics.

Advantages:

Smooth and fine edge or surface and small distortion.

Higher cutting speed and low cost, operation safe and stable function.

Imported servo motor and gearing system to guarantee precise cutting.

The dedicated software enables graphic or text to be instantly designed or processed.Flexible and easy operation.

Products applications: Sheet metal cutting Stainless steels cutting Spectacles frames cutting Accessories fabrications Hardware fabrications Automotives parts Advertisement arts Stainless steel decorations Kitchen appliances Stainless steel racks Stainless steel accessories Signboards Electrical appliances Signage, Furniture And more others which needed precision cutting of raw materials.

Applicable materials: Stainless steels Carbon steels Stainless iron Zinc coated iron sheets Aluminum alloys Aluminum Copper Rare metals And certain types of ceramics. Owing to the rich industry experience, we have been able to provide the customers with a commendable assortment of Laser Cutting and Engraving Machine. You simply won't find more feature-filled systems than those in the Laser Machine. Each feature has been designed with you in mind, and how you can get the most from the laser. You'll find features that improve connection capabilities, simplify project setup, and much more.

Laser welding is an advanced welding process technique, working with 4 axises control by the system, it able to welding various different shape items, the workpiece no distortion; no colour change; the weld point smooth, this laser welding machine widely applied to process jewellery; horologe; electric products; eyeglasses frame and some industries where require good welding effect.

The 4 axises linkage laser welding machine is able to do spot-welding, also can do the continuous welding; butt welding; stitch welding, seal welding, etc., the weld width small and heat-affected zone is small, no deformation.

Due to its characteristics of a high-beam quality, high penetration rate and transmission via fibres, Dynotech Instruments, with its global laser marking solutions is widely praised for precision spot welding. With adjustable supply output and a feedback control system for the laser power, helps stabilise the laser energy while also improving the consistency of the welding products. Our laser welding machine is most suitable for successful integration with automated production lines.

AconitySYSTEMS

LASER POWDER BED FUSION

Aconity3D offers several standard 3D printing machines, which cover a wide range of needs. On top, the machines can be modified easily by Aconity's modular platform and therefore enable tailor-made additive manufacturing solutions.

Aconity3D is specialized in the design and distribution of modular machine tools for powder bed based laser beam melting of metals. With the AconityPLATFORM, machines can be configured for your specific applications, thus extending the range of applications for this innovative manufacturing technology and allowing it to be used on an industrial scale. The open configurable Aconity3D systems combine maximum functionality with unique reliability. Our basic machine types, in combination with modular additional specifications, open up a wide range of application possibilities and can be tailored to specific customer requirements. Configure your system using our online machine configurator or contact our experienced staff for application-specific advice. We will support you at every stage, from identification and specification to the satisfaction of your specific needs. We look forward to hear from you.

Providing solutions for the most challenging industrial problems with decades of expertise in Laser welding technology

Laser micromachining offers the never witnessed before, a wide range of advantages for processing of materials in an ever-rising range of applications. Our laser micromachining and processing solutions support high-versatility solutions ranging from sub-micron tolerance to laser scribes that are kilometres long.

We provide an expansive range of laser technology that allows for the laser process to be in tune with the choice of material and the features, accompanied by high control over the interaction between the materials. We also master the control of laser energy delivery to an extent that our solutions can be effectively applied for thermal or heat-treatment procedures in addition to welding and vaporization for the purpose of high accuracy in micro-hole drilling procedures. The properties of our laser equipment allow for selective separation of one material from another, wherein the beam can be scanned to cater for features like laser marking, scribing, drilling, cutting, 3-D milling and dicing.

Making new applications possible with unique laser technologies that do what traditional fabrication techniques can’t.

Explore new engineering possibilities. OpTek has an extensive and innovative laser processing toolbox that enables applications that would be difficult or impossible to achieve with conventional optical fiber processing techniques.

Traditional abrasive and tool-based cleaving, lensing, and stripping methods are limited in the geometries they can achieve; are prone to abrasion, chipping, and other imperfections that can only be discovered in a separate inspection step; and can cause significant yield loss. OpTek’s laser-based methods solve all these issues—enabling simultaneous processing and inspection of precise design features for almost any specification, with virtually 100% first-pass yield.

Examples of our laser processing toolbox for fiber processing applications include:

1. Laser cleaving, including cylindrical, tapered, conical, angled and flat. These forms are used to provide high coupling efficiency between optical fibers and the laser source or receiver. Applications include telecommunications, data communications, fiber lasers, biomedical devices, energy exploration and production, gyroscopes, and a range of sensing applications.

2. Laser lensing, including conical, wedge, and biconic. High-performance lens forms are created directly on the end of optical fibers, with the unique ability to cleave and lens fibers already assembled into fixtures or ferrules. Applications include radial light emission for medical and dental procedures; probes for biomedical spectroscopy; light focusing for high-efficiency coupling with waveguides, source and detector coupling in telecom and military applications; and many others.

3. End capping. This reduces power densities to increase the damage threshold of the fiber component. It can also be used to modify beam shape emission through numerical aperture or mode field diameter manipulation or to modify beam direction and properties. Applications include high-energy beam delivery in defense, medicine, and a variety of sensing systems.

4. Laser stripping. Acrylate, polyimide, and other buffers can be removed through a non-contact process, with precise dimensional control for both end-stripping and window-stripping. Applications include medicine, defense, aerospace, undersea, and others that require ultra-high reliability. Advanced fiber assemblies: OpTek can also build complete, turnkey fiber optic assemblies for any application requirement, including terminators and connectors, feed-through tubes, solders, fiber Bragg gratings, and harsh-environment probes. With a single source for complete fiber assemblies, you can simplify your supply chain and count on reliable delivery and performance.

Whether you contract the work to OpTek or perform it yourself using OpTek technology, we help make your innovative new designs manufacturable. Let’s talk about your ideas and how to bring them to reality.

Shaping a safer, more efficient autonomous vehicles since decades

As a partner for provision of technological solutions, we empower our customers in the automotive industry with customer-centric and flexible laser systems. Our innovative solutions help bring futuristic automotive parts to life, be it the engine management or sensors the auto drive feature. At Dynotech Instruments, we thoroughly understand the importance of delivering the right service and equipment for effective functioning of all automotive industrial practices.

AUTOMOTIVE - MOBILE AND INNOVATIVE

As a technology partner, we inspire our customers in the automotive industry with highly flexible and customer-specific laser systems. We realize innovative joining solutions for future-oriented vehicle components from the interior, the drive train, to components for engine management, sensors for autonomous driving, electric drives or batteries. Our systems used worldwide are designed for smooth 24/7 production. We know how important the customers of our customers are and we can deliver the right service in the Evosys Group at the same time.

Reliable and safe medtech instruments that support constant development of new treatment methods

The consistency in the development of novel diagnostic and treatment processes has led to a rise in the significance of developing production processes in the healthcare sector that are reliable. We support you with our solutions backed by years of experience and expertise that help with the production processes in the medtech industry starting from the very initial developmental steps up to the final production outcomes. Facilitating the execution of top-priority Medtech requirements is our motto and our laser welding equipment help serve that meeting the GMP standards.

MEDTECH - SAFE AND RELIABLE

The constant development of new treatment methods is rapidly increasing the importance of reliable production processes in the healthcare sector. We support you with our engineers and their many years of experience in this field from the very first development steps for new products and associated joining tasks through to complete solutions for your production. Absolute reliability, complete documentation and the implementation of the highest cleanliness requirements are always in the foreground. Laser welding of plastics is the ideal process to meet these requirements. Production according to GMP standards is easy to ensure with EVOSYS equipment.

Facilitating particle-free and cost-effective operations through laser welding technology for plastics

Innovative designs and high-quality packaging are the requests that we most commonly encounter in the consumer industry. With our in-depth knowledge and expertise of a wide range of production processes, we provide the solutions and support that the consumer industry is exactly looking for. Dynotech Instruments’ equipment for laser welding of plastics is the best choice for the consumer industry.

CONSUMER - FAST AND EFFICIENT

Miniaturization, design and extreme packing density are the most common requests we encounter in the field of consumer products. With our process and production knowledge we provide support at an early stage. This means that targets can usually be exceeded. But laser welding of plastics can also be the best option for everyday products. EVOSYS systems are the best choice in any case.

The EvoWeld is a universal machine for plastic welding with laser, especially for the processing of small and medium series. Depending on the application, the system can be equipped with different laser sources and optical modules, thus offering a wide range of applications.

With a footprint of approx. 1 m², the system fits into any application environment. Virtually maintenance-free and service-friendly, the EvoWeld is predestined for use in 24/7 production. For comfortable operation, the system is equipped with the intuitive EvoLaP process software as standard and can therefore also implement a wide range of different processing tasks in the field of laser welding of Plastics.